IEC 61439 Verification Methods

The (relatively new) switchgear and control gear standard, IEC 61439 'Low-voltage switchgear and controlgear assemblies' , ensures compliance to the standard by a series of design and routine verifications.

The (relatively new) switchgear and control gear standard, IEC 61439 'Low-voltage switchgear and controlgear assemblies' , ensures compliance to the standard by a series of design and routine verifications.

Design Verifications

The standard has three methods which can be used to verify the design characteristics of an assembly will meet the standard. These are verification by test, verification by calculation and verification by the use of design rules.

The following table (table D.1 from Annex D of the standard, IEC:2011) summarizes each characteristic and the allowable options for design verification:

| |

|

|

Verification options |

| No. |

Characteristics to be verified |

Clauses or

subclauses |

Testing |

Calculation |

Design

Rules |

| 1 |

Strength of materials and parts:

Resistance to corrosion

Properties of insulating materials:

Thermal stability

Resistance of insulating materials to abnormal

heat and fire due to internal electric effects

Resistance to ultraviolet (UV) radiation

Lifting

Mechanical impact

Marking |

10.2

10.2.2

10.2.3

10.2.3.1

10.2.3.2

10.2.4

10.2.5

10.2.6

10.2.7 |

YES

YES

YES

YES

YES

YES

YES |

NO

NO

NO

NO

NO

NO

NO |

NO

NO

YES

YES

NO

NO

NO |

| 2 |

Degree of protection of the enclosures |

10.3 |

YES |

NO |

YES |

| 3 |

Clearances |

10.4 |

YES |

NO |

NO |

| 4 |

Creepage distances |

10.4 |

YES |

NO |

NO |

| 5 |

Protection against electric shock and integrity

of protective circuits:

Effective continuity between the exposed conductive

parts of the assembly and the protective circuit

Short-circuit withstand strength of the protective

circuit |

10.5

10.5.2

10.5.3 |

YES

YES |

NO

YES |

NO

NO |

| 6 |

Incorporation of switching devices and components |

10.6 |

NO |

NO |

YES |

| 7 |

Internal electrical circuits and connections |

10.7 |

NO |

NO |

YES |

| 8 |

Terminals for external conductors |

10.8 |

NO |

NO |

YES |

| 9 |

Dielectric properties:

Power-frequency withstand voltage

Impulse withstand voltage |

10.9

10.9.2

10.9.3 |

YES

YES |

NO

NO |

NO

YES |

| 10 |

Temperature-rise limits |

10.10 |

YES |

YES |

YES |

| 11 |

Short-circuit withstand strength |

10.11 |

YES |

YES |

NO |

| 12 |

Electromagnetic compatibility (EMC) |

10.12 |

YES |

NO |

YES |

| 13 |

Mechanical operation |

10.13 |

YES |

NO |

NO |

Routine Verification

Routine verification is carried out the detect faults in workmanship and the correct functioning of the panel. The standard (IEC:2011) list the following:

- Construction (see 11.2 to 11.8)

- degree of protection of enclosures

- clearances and creepage distances

- protection against electric shock and integrity of protective circuits

- incorporation of built-in components

- internal electrical circuits and connections

- terminals for external conductors

- mechanical operation

- Performance (see 11.9 to 11.10)

- dielectric properties

- wiring, operational performance and function

Original and Assembly Manufacturer

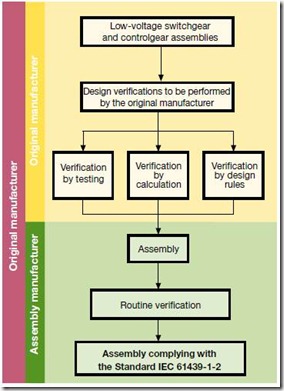

IEC 61439 Verification, Courtesy ABB The standard also tries to explain the differing roles of the original panel manufacturer and a assembly manufacturer. The original manufacturer is the party who initially carries out the panel design and arranges for the necessary design verifications to be performed. The assembly manufacturer is the party who finally builds the panel to the customers requirements and delivers it. The image shows the relationship between the parties and who performs the verification.

Note: if an assembly manufacturer incorporates his own arrangements, he is then deemed to be the original manufacturer by the standard.

In addition to this post, you may also be interested in my post on 'Forms of Internal Separation' according to the standard:

Switchboard - Forms of Internal Separation