Harmonised Cable Codes and Colours

Within Europe the European Committee for Electrotechnical Standardization (CENELEC) has standardised the both the designation and colour of cables. These are published in CENELEC document HD 361 S3:1999 "System for cable designation" and HD 308 S2: 2001

"Identification of cores in cables and flexible cords". This note provides a general overview to the harmonised system and gives some examples.

Cable Designation

The HD 261 document, classifies the construction of the cable by allocating codes (letters or numbers) to represent the cable voltage, insulation material\, structural elements, sheath, special features and conductor type.

For a full list of codes and their meanings, it is best to refer to the standard. A typical cable specification would take the form of:

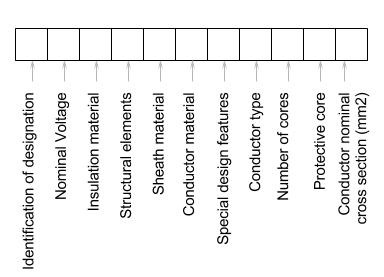

Laying out the Harmonised Cable Code

The layout of the cable code can be split into three parts. Fist the standard and nominal voltage are given. This is followed by the insulation material, construction features and sheath. Finally the cores and cross section are specified.

Each cable element is designated with a alpha numeric code as detailed in the tables below. Typically these are connected together to form the final cable designation. Optional codes or codes that have no relevance to the cable under consideration are simply omitted.

Note: some codes are preceded by a '-' sign, for example -A (aluminium).

Designation Codes

| Identification of Designation

A authorised national standard

H harmonised standard

Nominal Voltage

01 100 V

03 300/300 V

05 300/500 V

07 450/750 V

Structural Elements

- Concentric Conductors

A Concentric aluminium conductor

A6 Concentric aluminium conductor, meander-shaped

C Concentric copper-conductor

C6 Concentric copper-conductor, meander-shaped

C9 Divided concentric copper conductor

- Screen

A7 Aluminium screen

A8 Aluminium screen, individual conductors

C4 Copper braid screen

C5 Copper braid screen, individual conductors

C7 Copper tape screen

C8 Copper tape screen, individual conductors

D Screen of one or more thin steel tapes

- Armouring

Z2 Armouring of round steel wires

Z3 Armouring of flat steel wires

Z4 Armouring of steel tape

Z5 Braiding of steel wires

Z6 Supporting braid of steel wires

Z7 Armouring of sectional steel wires

Y2 Armouring of round aluminium wires

Y3 Armouring of flat aluminium wires

Y5 Armouring of special materials

Y6 Armouring of steel wires and/or tape and copper wires

Conductor Material

w/o designation Copper

- A Aluminium

- Z Special material and/or special shape

Special Design Features

- Supporting Structures

D2 Textile or steel wires over cable conductor

D3 Textile elements stranded in conductor cable

D4 Self-supporting cables and wires

D5 Central conductor element

- Special Versions

w/o designation round cable construction

H Flat type as separable cables with or without jacket

H2 Flat type of cables not separable

H3 Building Cable, flat webbed

H4 Multi conductor flat cable with one plain conductor

H5 Two or more single conductor stranded, non-jacket

H6 Flat cables with 3 or more conductors

H7 Cable with two-jacket extruded insulation

H8 Coiled conductor

Conductor Type

- D fine wire stranded for welding cables

- E extra fine wire stranded for welding

cables

- F fine wire stranded for flexible cables

- H extra fine wire stranded for flexible cables

- K fine wire stranded conductor for fixed installation

- M Milliken conductor

- R conductor of multi stranded wires

- S sector-shaped conductor of multi stranded wires

- U round conductor of single wire

- W sector-shaped conductor of single wire

- Y tinsel conductor

- Z conductor of special material

Protective Core

G with green/yellow earth conductor

X without earth conductor | Insulation & Sheath Materials

B Ethylene-propylene rubber (EDR) +90°C

B2 Ethylene-propylene rubber (EDR), hardened

B3 Butyl rubber

E Polyethylene

E2 Polyethylene, high density

E4 Poly-tetrafluorethylene

E5 Eethylene propylene rubber

E6 Ethylene tetrafluorethylene

E7 Polypropylene

G Ethylene-vinylacetate (EVA)

J Glass fibre braiding

J2 Glass fibre wrapping

M Mineral insulation

N Chloroprene rubber (CR)

N2 Chloroprene-rubber (CR), welding cable

N4 Chlorinated polyethylene

N5 Nitril-rubber

N6 Fluorinated rubber

N7 PVC nitril rubber compound

N8 Polychloroprene rubber, water resistant

P Impregnated paper insulation

Q Polyurethane (PUR)

Q2 Polyethyleneterephthalate

Q3 Polystyrole

Q4 Polyamide

Q5 Polyamide

Q6 Polyvinylidene fluoride

R (NR, SR) natural or synthetic rubber

S (SIR) silicone rubber

T Textile braiding

T2 Textile braiding with flame retardant

T3 Textile conductor wrapping or tape

T4 Textile conductor wrapping or tape, flame retardant

T5 Corrosion protection

T6 Textile braiding over individual conductor or cable

V PVC

V2 PVC soft, resistant to increased temperature, +90°C

V3 PVC soft, for low temperatures

V4 PVC soft, cross-linked

V5 PVC soft, oil resistant

X Cross-linked polyethylene

Z Cross-linked compound, LSZH

Z1 Thermoplastic compound, LSZH

Note: for details in insulation properties, please refer to:

- Cable Insulation Properties |

Cable Code Examples

Different manufacturers vary the way in which they present the harmonized designation for their cables. Here are a few examples of varying cable designations:

- H05VV5-F 2G075 is 00/500 V, PVC insulated, PVC sheathed, stranded flexible conductor, 2 core 2.5 mm2 with protective conductor

- H05V-K 1X1 is 300/500 V, PVC insulated, fine wire stranded, single core 1 mm2 with no protective conductor

- S03VV-F 3G0.75 is national standard (VDE in this case), 300/300 V, PVC insulated, PVC sheathed, fine wire stranded flexible cable, 3 core 0.75 mm2 with protective conductor

- H07RV-F 3X10 is 450/750 V, natural rubber insulation, PVC sheath, fine wire stranded, three core 10 mm2 with no protective conductor

- H05Z-K 1X2.5 is 300/500 V, XLPE LSZH, fine wire stranded, single core 2.5 mm2 without protective conductor

Cable Colour Codes

CENELEC (including BS 7671 - IEE Wiring Regulations)

| Function | Alpha-

numeric | Colour |

| Protective conductors | | Green and yellow |

| Functional earthing conductor | | Cream |

| a.c. power circuit |

| Phase of single-phase circuit | L | Brown  |

| Neutral of single- or three-phase circuit | N | Blue  |

| Phase 1 of three-phase a.c. circuit

| L1 | Brown  |

| Phase 2 of three-phase a.c. circuit | L2 | Black  |

| Phase 3 of three-phase a.c. circuit | L3 | Grey  |

| Two-wire unearthed d.c. power circuit |

| Positive of two-wire circuit | L+ | Brown  |

| Negative of two-wire circuit | L- | Grey  |

| Two-wire earthed d.c. power circuit |

| Positive (of negative earthed) circuit | L+ | Brown  |

| Negative (of negative earthed) circuit | M | Blue  |

| Positive (of positive earthed) circuit | M | Blue  |

| Negative (of positive earthed) circuit | L- | Grey  |

| Three-wire d.c. power circuit |

| Outer positive of two-wire circuit derived from three-wire system | L+ | Brown  |

| Outer negative of two-wire circuit derived from three-wire system | L- | Grey  |

| Positive of three-wire circuit | L+ | Brown  |

| Mid-wire of three-wire circuit | M | Blue  |

| Negative of three-wire circuit | L- | Grey  |

| Control circuits, ELV and other applications |

| Phase conductor | L | Brown, Black, Red, Orange,

Yellow, Violet, Grey, White, Pink or Turquoise |

| Neutral or mid-wire | N or M | Blue |

If anyone notices any mistakes or corrections which are needed, please leave a comment below.