Cable Sizing Tool

Our cable sizing tool is one of the more popular tools on the site. The tool enables cables to be sized in compliance with BS 7671 (the IEE Wiring Regulations) and by implication IEC 60364.

Our cable sizing tool is one of the more popular tools on the site. The tool enables cables to be sized in compliance with BS 7671 (the IEE Wiring Regulations) and by implication IEC 60364.

This post gives some insight into how the tool works, the calculations carried out and how to use it. With the tool being based on BS 7671, this post will also provide an introduction and explanation of the cable sizing method given in the standard.

The sizing tool can be found at:

myElectrical Cable Sizing Tool

The Procedure

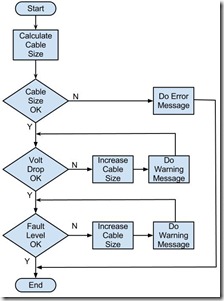

The flowchart (click for a larger image) shows the general procedure followed by the tool:

- current capacity – a cable size is found which is adequate for the expected current

- voltage drop – the voltage drop on the selected cable is checked and if to big the cable size is increased

- fault level – the fault level withstand is checked and if not adequate the cable size is increase

Any errors or warnings generated during the calculation are passed on the the user.

In addition to cable size the tool also calculates the cable impedance and fault levels at the load end of the cable.

The Formulae

The calculation method follows the procedures given in BS 7671:2008 (the IEE Wiring Regulations), 17th Edition.

Definitions:

Iz - current carrying capacity of the cable (continuous service under defined installation conditions)

It - tabulated value of current (for the type of cable, type of installation, and at an ambient of 30oC)

Ib - design current of the circuit (expected in normal service)

In - nominal setting of any protective device

I2 – operating current of the protective device

Ca - correction factor for the ambient temperature

Cc - correction factor for the type of protective device used

Cg - correction factor for grouping of circuits/cables

Ci - correction factor thermal insulation

Ct - correction factor for the operating temperature of the conductor

Np - number of cables in parallel

tp - maximum permitted operating temperature

Current Capacity

By considering any correction factors, the tabled current for a cable installed in a given situation can be found. Once the tabled value of current is found, the cable size is determined by selecting the next largest cross sectional area in the lookup tables.

For single circuits:

For groups where simultaneous overload is possible:

For groups not liable to simultaneous overload (the maximum of):

For cables where overload protection is not required:

Once It is known, this size of cable is then looked up in the current carrying capacity tables:

- Tables 4D1A to 4J4A (pages274 to 316) – current carrying capacity

Correction factors are obtained from the following tables (dependant upon cable type and installation):

- Table 4B1 – rating factors for cables in air, ambient other than 30 °C

- Table 4B2 – rating factors for buried cables, ambient other than 20 °C

- Table 4B3 – rating factors for buried cables, thermal resistivities other an 2.5 K.m.W-1

- Table 4C1 to 4C3 – rating for grouping of circuits/cables

- Table 52.2 – rating factors for cables surrounded by thermal insulation

Voltage Drop

Voltage drop calculations consider both the power factor of the system and a correction factor for the cable operating standard. Tables 4D1B to 4J4B of the standard give voltage drops (resistive and reactive) in (mV/A/m), which is equivalent to mΩ/m (or Ω/m if adjusted).

By looking up in these tables and using the cable length, the sizing tool determines the resistance, R and reactance, X of the cable. The calculated voltage drop, is then given by:

The temperature correction factor is only applied to the resistance and is given by:

Note: the tool carries out all calculations in complex form.

Fault Levels

The fault withstand rating of the cable is determined using the adiabatic equation:

Where:

S is the cable cross sectional area in mm2

I is the fault current which can flow in A

t is the operating time of the protective device in S

k is a factor related to the conductor material and insulation – tables 54.2 to 54.6 of the standard

Frequently Asked Questions

How does the tool taking into account parallel conductors?

Additional parallel cables are automatically added to group derating (you don't need to increase this manually).

You can click the ignore checkbox to change this (for example if your cables are more than two diameters apart).: code changes have been made. The updated version of the calculator is now live.

What exactly is the No.Circuits/Cables?

Group derating takes into account heat generated by adjacent cables. Each circuit is usually supplied by one cable and the number of circuits will equal the number of cables. Sometimes several cables are run a parallel for a single circuit and this will increase the total number of cables (and group derating).

Tip: if cables are spaced more than twice their overall diameter apart, then no group derating is required.