Hazardous Areas – IEC and NEC/CEC Comparison

Sasol, South Africa

Sasol, South Africa Depending on where in the world you work, you are likely following one of two standards

- International Electrotechnical Commission (IEC)

- National Electrical Code/Canadian Electrical Code (NEC/CEC)

The different nature of the two systems makes a direct comparison almost impossible.

If you do need to work with both systems or transition from one to the other, hopefully, the following will make this easier.

Since July 2003, Ex products in Europe must also be certified to the ATEX directive (ATEX 94/9/EC).

Zones & Divisions

| IEC Classification IEC 60079 |

|

ANSI/NFPA 70 NEC Article 500 |

| Gas and Vapours |

| Zone 0 |

flammable atmosphere highly likely to be present - may be present for long periods or even continuously |

| Zone 1 |

flammable atmosphere possible but unlikely to be present for long periods |

| Zone 2 |

flammable atmosphere unlikely to be present except for short periods of time - typically as a result of a process fault condition |

| Dusts |

| Zone 20 |

dust cloud likely to be present continuously or for long periods |

| Zone 21 |

dust cloud likely to be present occasionally in normal operation |

| Zone 22 |

dust cloud unlikely to occur in normal operation, but if it does, will only exist for a short period |

|

|

| Class (nature of the material) |

| Class I |

hazardous because flammable gases or vapors are present in the air in quantities sufficient to produce explosive or ignitable mixtures |

| Class II |

hazardous because combustible or conductive dusts are present |

| Class III |

hazardous because ignitable fibers or flying's are present, but not likely to be in suspension in sufficient quantities to produce ignitable mixtures. |

| Division (probability of material being present) |

| Division 1 |

the substance referred to by class is present during normal conditions |

| Division 2 |

the substance referred to by class is present only in abnormal conditions, such as a container failure or system breakdown |

|

Temperature & Explosion Groups

| Explosion Groups |

|

Temperature Class |

| |

IEC |

NEC/CEC |

| Inflammable material |

Zone |

Group |

Class |

Division |

Group |

| Gas and Vapours |

| Acetylene |

0,1 or 2 |

II C |

I |

1 or 2 |

A |

| Hydrogen |

0,1 or 2 |

II B+H2 |

I |

1 or 2 |

B |

Propylene oxide

Ethyl oxide

Butadiene |

0,1 or 2 |

II B |

I |

1 or 2 |

B |

Cyclopropane

Ethly ether

Ethylene |

0,1 or 2 |

II B |

I |

1 or 2 |

C |

Acetone

Benzene

Butane

Hexane

Paint solvents

Natural gas |

0,1 or 2 |

II A |

I |

1 or 2 |

D |

| Dusts |

| Metal dust |

|

III C |

II |

|

E |

| Coal dust |

|

III C |

II |

|

F |

| Grain dust |

|

III B |

II |

|

G |

Wood

Paper

Cotton |

|

III A |

III |

|

|

|

|

Temperature

oC |

IEC |

NEC/CEC |

| 85 |

T6 |

T6 |

| 100 |

T5 |

T5 |

120

135 |

T4

T4 |

T4A

T4 |

160

165

180

200 |

T3

T3

T3

T3 |

T3C

T3B

T3A

T3 |

215

230

260

280

300 |

T2

T2

T2

T2

T2 |

T2D

T2C

T2B

T2A

T2 |

| 450 |

T1 |

T1 |

|

| Gas Group / Temperature Class |

| Group |

T1 |

T2 |

T3 |

T4 |

T5 |

T6 |

| I |

Methane |

|

|

|

|

|

| IIA |

Acetone

Methane

Ethane

Benzene

Methanol

Toluene

Propane

Acetic Acid

Ammonia

|

Ethanol

Cyclohexane

Propanol 2

N-Butyl alcohol

N-butane |

Diesel fuel

Aircraft fuel

Fuel oil

N-Hexane

Heptane

Kerosene |

Acetaldehyde

|

|

|

| IIB |

Coal Gas |

Ethylene

Ethylene oxide

Propanol 1

Methyl Ethyl

Ketone |

Ethylene glycol

Hydrogen Sulphide

Tetrahydrofuran |

Ethyl Methyl Ether

|

|

|

| IIC |

Hydrogen |

Acetylene |

|

|

|

|

|

|

| Ignition Temperatures for Common Flammable Dusts and Fibers |

| |

Ignition Temperature |

| Material |

Cloud |

Layer |

| Coal Dust |

380°C |

225°C |

| Polythene |

420°C |

(melts) |

| Methyl Cellulose |

420°C |

320°C |

| Starch |

460°C |

435°C |

| Flour |

490°C |

340°C |

| Sugar |

490°C |

460°C |

| Grain Dust |

510°C |

300°C |

| Phenolic Resin |

530°C |

> 450°C |

| Aluminium |

590°C |

> 450°C |

| PVC |

700°C |

> 450°C |

| Soot |

810°C |

570°C |

|

Equipment & Protection Levels

IEC/ATEX Equipment Protection

Level (EPL) |

|

IEC Equipment Classification |

| IEC 60079 |

|

94/9/EC (ATEX) |

EPL |

Zone(s) |

Group |

Category |

Protection

Level |

| Gas/Vapours |

| Ga |

0,1,2 |

II |

1 G |

very high |

| Gb |

1,2 |

II |

2 G |

high |

| Gc |

2 |

II |

3 G |

increased |

| Dusts |

| Da |

20,21,22 |

III |

1 D |

very high |

| Db |

21,22 |

III |

2 D |

high |

| Dc |

22 |

III |

3 D |

increased |

| Methane, Coal Dust |

| Ma |

Mining |

I |

M1 |

very high |

| Mb |

Mining |

I |

M2 |

high |

NEC/CEC Equipment Classification

| Method of Protection |

Division |

| Intrinsic Safety, IS |

1 or 2 |

| Explosion-Proof, XP |

1 or 2 |

| Pressurization, X,Y,Z |

1 or 2 |

| Non-incendive equipment |

2 |

|

Specifically assessed equipment

|

2 |

|

|

| Code |

Description |

EPL |

Type of Protection |

| Ex e |

Increased safety |

Gc |

Intended to prevent a potential ignition arising |

| Ex n |

Type - n protection |

Gc |

| Ex ia |

Intrinsic safety 'ia' |

Ga |

Intended to limit the ignition energy of the equipment |

| Ex ib |

Intrinsic safety 'ib' |

Gb |

| Ex ic |

Intrinsic Safety 'ic' |

Gc |

| Ex n |

Type - n protection |

Gc |

| Ex p |

Purge/pressurized protection |

Gb |

Intended to prevent the explosive atmosphere contacting the ignition

source |

| Ex px |

Purge/pressurized protection 'px' |

Gb |

| Ex py |

Purge/pressurized protection 'py' |

Gb |

| Ex pz |

Purge/pressurized protection 'pz' |

Gc |

| Ex m |

Encapsulation |

Gb |

| Ex ma |

Encapsulation |

Ga |

| Ex mb |

Encapsulation |

Gb |

| Ex o |

Oil immersion |

Gb |

| Ex n |

Type - n protection |

Gc |

| Ex d |

Flameproof protection |

Gb |

Intended to prevent an ignition from escaping outside the equipment |

| Ex q |

Sand / powder (quartz) filling |

Gb |

| Ex nC |

Type - n protection |

Gc |

| Ex s |

Special protection Refer to equipment marking and documentation |

|

Degrees of Protection

Ingress Protection Codes

IPxx (IEC 60079) |

|

NEMA Enclosure Types (& IEC IP Equivalent) |

| x |

1st Numeral

Solid Bodies |

2nd Numeral

Liquids |

3rd (optional)

Impact |

| 0 |

No protection |

No protection |

No protection |

| 1 |

Objects > 50 mm dia. |

Vertically dripping water |

0.225 Joule |

| 2 |

Objects > 12.5 mm dia. |

Angled dripping water (up to 15o) |

0.375 Joule |

| 3 |

Objects > 2.5 mm dia. |

Spraying water (up to 60o) |

0.5 Joule |

| 4 |

Objects > 1.0 mm dia. |

Splashing water (all directions) |

2.0 Joule |

| 5 |

Dust protected |

Low pressure water jets |

6.0 Joule |

| 6 |

Dust tight |

High pressure water jets |

20.0 Joule |

| 7 |

|

Temporary immersion |

|

| 8 |

|

Continuous immersion |

|

|

|

| Type |

Area |

Description |

IP |

| 1 |

Indoor |

General Purpose |

10 |

| 2 |

Indoor |

Drip proof protection against falling water and dirt |

11 |

| 3 |

Indoor

Outdoor |

Dust & rain tight protection against windblown dust, rain, and sleet & damage from formation of ice |

54 |

| 3R |

Outdoor |

Rain proof & ice/sleet proof protection against falling rain & damage from formation of ice |

14 |

| 3S |

Outdoor |

Dust tight, rain tight, & ice/sleet proof protection against sleet and damage from formation of ice |

55 |

| 4 |

Indoor

Outdoor |

Water tight & dust tight |

66 |

| 4X |

Indoor

Outdoor |

Water tight, dust tight, & corrosion resistant protection from corrosion, hose directed water and damage from formation of ice |

66 |

| 5 |

Indoor |

Dust tight & drip tight protection against dust, fibres, falling dirt, and dripping non-corrosive liquids |

52 |

| 6 |

Indoor

Outdoor |

Temporary submersion protection against falling dirt, dust, fibres, hose directed water and temporary submersion in water |

67 |

| 6P |

Indoor

Outdoor |

Prolonged submersion protection against falling dirt, dust, fibres, hose directed water and prolonged submersion in water |

67 |

| 7 |

Indoor |

Class I, Division 1, Groups A, B, C, and D hazardous locations, air-break equipment |

|

| 8 |

Indoor

Outdoor |

Class I, Division 1 Groups A, B, C, and D hazardous locations, oil-immersed equipment |

|

| 9 |

Indoor |

Class II, Division 1, Groups E, F, and G hazardous locations, air-break equipment |

|

| 10 |

Mining |

Mining applications |

|

| 12 |

Indoor |

Dust tight & drip tight protection against dust, fibres, falling dirt, and dripping non-corrosive liquids (enclosure without knockouts) |

52 |

| 12K |

Indoor |

Dust tight & drip tight protection against dust, fibres, falling dirt, and dripping non-corrosive liquids (enclosure with knockouts) |

52 |

| 13 |

Indoor |

Dust tight & oil tight protection against dust, spraying of water, oil, and noncorrosive coolant. |

54 |

|

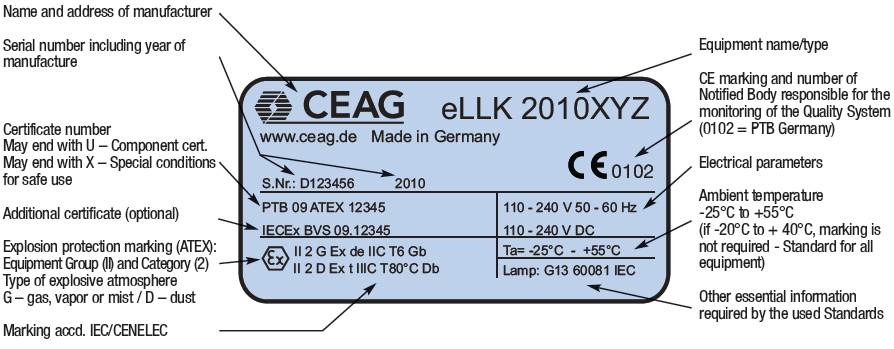

Product Markings

Typical IEC Type Marking

Typical NEC/CEC Type Marking

As a general rule equipment should be marked as follows:

- Company/Manufacturers name

- Class I, II and/or III

- Division 1 and/or 2

- Group A, B, C, D, E, F and/or G

- Approving NRTL (Nationally Recognized Testing Laboratory) logo

- Product identification

- Serial number

- Other relevant safety information

- Enclosure Type Rating

Finally

Finally the end... When I started this post I thought it would be one of the easier ones - reproduce and sort a few tables and I'm done. Well, it took a lot longer than I had anticipated and quite a bit more work. Anyhow now that it's finished I relieved. Having said that, if anyone notices any errors or has suggestions to improve the post, please add them below and I'll update the post as necessary.