Battery Sizing

This article gives an introduction to IEEE 485 method for the selection and calculation of battery capacity.

Definitions

- battery duty cycle - the load (including duration) the battery is expected to supply

- cell size - rated capacity of the battery

- equalizing charge - prolonged charge, at a rate higher than the normal float voltage

- full float operation - operation with the batteries and load connected in parallel

- period - time during which load is expected to be constant during sizing calculations

- rated capacity - capacity of the battery cell (usually for a given discharge rate and end of cell voltage)

- valve-regulated lead-acid (VRLA) cell - sealed lead-acid cell (with the exception of a valve that opens when the internal pressure exceeds the external pressure)

- vented battery - battery in which the products of electrolysis and evaporation are allowed to escape freely to the atmosphere

Battery Selection

The selection of the physical [[batteries|battery]] (cells) is dependant on several factors:

- type of battery (sealed, vented, lead acid, NiCad, etc.)

- expected life of the battery

- usage of the batter (number of charge/discharge cycles)

- dimensions and weight of the battery

- construction materials

- connectors and terminals

- ambient environment and conditions

- maintenance requirements

- seismic characteristics

Ampere-hour and Watts/cell

The Ah or Ampere-hour capacity is the current a battery can provide over a specified period of time. For example 100Ah @ C10 rate to end of discharge of 1.75 V/cell means the battery can provide 10 Amps for 10 hours to an end of discharge voltage of 1.75 V per cell.

Different battery manufacturers will use different Cxx rates depending on the market or application at which their batteries are targeted. Typical rates used are C3, C5, C8, C10 and C20. Because of this it is important, when comparing batteries from different manufacturers.

Ah is used for sizing batteries based on constant [[electric current|current]] methods and watts/cell on constant [[Electrical Power|power]] methods.

IEEE 485 Lead Acid Batteries for Stationary Applications

This standard details methods for defining the dc loads and for sizing a lead-acid battery to supply those loads in full float operation. A brief description of the method presented by the standard follow. For a full and accurate description, refer to the full standard.

Load Definition

Loads are classified as:

- continuous - loads continually present

- non-continuous - loads lasting for a specific period

- momentary - loads lasting for less than 1 minute

Typical Loads Continuous

| Non-continuous

| Momentary |

Lighting

Continuous Motors

Converters

Indicating Lights

UPS

Control Systems | Emergency motors

Fire protection systems

Valve operations ( > 1 min) | Switchgear operations

Valve operations ( < 1 min)

Isolating switch operations

Field flashing of generators

Motor starting currents

Inrush currents |

Note: commonly momentary loads are assumed to last for 1 minute during battery sizing calculations.

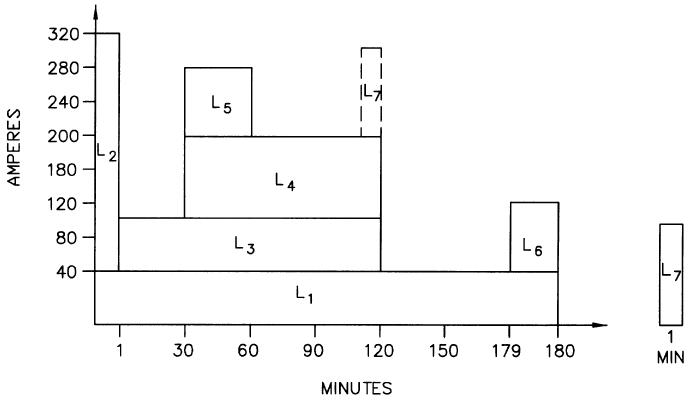

Duty Cycle Diagram

The standard recommends a duty cycle be drawn showing the anticipated loads (in [[Ampere]] or power) for the required duration of battery backup time.

The standard recommends a duty cycle be drawn showing the anticipated loads (in [[Ampere]] or power) for the required duration of battery backup time.

IEEE 485 Std. Recommended Practice for Sizing Lead Acid Batteries for Stationary Applications - Typical Duty Cycle

Considerations

- loads and times where known should be shown

- random loads should be shown at the most critical times

Calculation of Battery Size

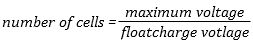

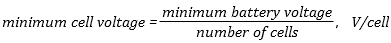

Number of Cells and Cell Voltage - the number of cells is estimated based on the maximum battery voltage and float charge voltage:

The minimum battery voltage is the minimum system voltage (including voltage drops across cables). Given the minimum cell voltage the minimum cell voltage is given by:

Temperature Correction - at temperature decreases the capacity of a cell decreases (and vise verse as the temperature increases). Manufacturers quote cell capacity at a given temperature and appropriate correction factors should be used for other temperatures.

Aging Factor - battery performance is relatively stable through out its life, dropping of rapidly towards the end. To ensure the battery can meet the design requirements throughout its life the standard suggestions the initial capacity should be 125% of the design capacity.

Design Margin - to cater for unexpected circumstances (increased loads, poor maintenance, recent discharge, etc.) it is common to allow a design margin of 10% to 15%.

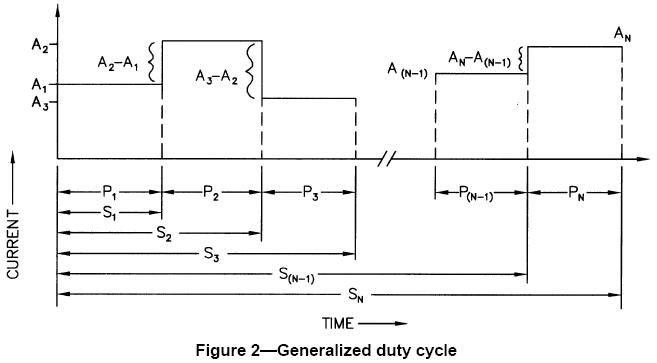

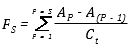

Sizing Methodology - the required capacity of the cell FS is given by:

Sizing Methodology - the required capacity of the cell FS is given by:

Where S can be any integer from 1 to N depending on the section being calculated and FS is expressed in watt-hours or ampere-hours depending on which Ct is used.

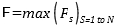

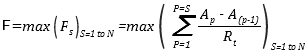

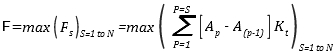

The required uncorrected cell size F, is then given by:

where:

- F - is the uncorrected (temperature, aging and design margin) cell size

- S - is the section of duty cycle being studied (containing all previous sections)

- N - is the number of periods in the duty cycle

- P - is the period being analysed

- AP - the amperes required for period P

- t - the time in minutes from the beginning of period P through the end of Section S

- Ct - is the capacity rating factor (for a given cell type, at the t minute discharge rate, at 25 °C, to a definite minimum cell voltage

- FS - is the capacity required by each section

Capacity rating factor

There are two ways of expressing capacity:

Term Rt

The term Rt is the number of amperes each plate can supply for t minutes, at 25oC to a defined minimum cell voltage.

giving:

Term Kt

The term Kt is the ratio of ampere-hour capacity, at a standard time rate, at 25oC and to a defined minimum voltage which can be delivered for t minutes.

giving:

Rt is not equal to 1/Kt because each factor is expressed in different units.

See Also

References

- [1] IEEE Std. 485 'IEEE Recommended Practice for Sizing lead-Acid Batteries for Stationary Applications, Institute of Electrical and Electronics Engineers