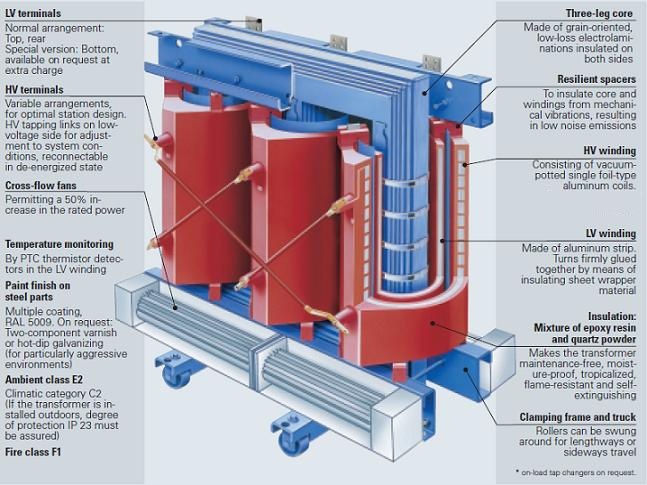

Aluminium Windings - Dry Type Transformers

The other day I was talking to a colleague who is a building services consultant. Despite regularly specifying dry-type/cast resin transformers he was unaware that many manufacturers use aluminium for the windings; I think Siemens exclusively use aluminium and don’t offer copper anymore. To confirm this he promptly phoned Schneider Electric and was informed that they use aluminium (or copper on request).

This reminded me of a few years ago when I was working for a contractor and wanted to install Siemens transformers on a large international airport. Siemens was one of the three preferred vendors; however the airport’s specification called for copper windings. Because of the specification the airport refused the transformers for weeks (we even had the Siemens factory guys out from Germany). The client’s agreement in the end was not driven by technical considerations, but by contractual/time delay issues. Transformers were installed and as far as I know are still happily humming away.

The illustration of a Siemens GEAFOL transformer shows the HV and LV aluminium windings. The HV windings are wound from aluminium foil interleaved with an insulating foil. The LV windings are wound form single-aluminium sheets and interleaved with cast-resin impregnated fibreglass fabric. Foil type windings are subject to less electrical stress than conventional windings resulting in higher AC and impulse voltage withstand characteristics. Thermal expansion coefficients of aluminium and cast resin are similar and resulting thermal stress due to load change is kept to a minimum.

To my mind, compliance with the performance requirements of the manufacturing standards is the important criteria and the constructional aspects (aluminium or copper) are not that significant. As a final practical tip, during the above airport installation copper cable was being terminated onto the aluminium terminals of the transformer. In this instance bi-metallic plates were inserted between the cable lugs and transformer terminals.